(01) Set various parameters for equipment operation through the touch screen on the device. The operator manually places the workpiece into the cleaning fixture basket and places it at the feeding station. The motor drives the conveyor chain to automatically drive the fixture basket into the sensing area and enter the working state; Internal automatic positioning is used in conjunction with a robotic arm to grab the fixture basket, which enters the spraying, jetting, and emptying stations (cleaning solution: municipal water+degreaser). After the fixture basket reaches the cleaning station, the running device stops and the high-pressure spraying device starts working, starting high-pressure spraying cleaning. The nozzle is set above and on the side of the tank, and the liquid is thoroughly filtered before rinsing the workpiece during spraying cleaning. During the flushing process, add liquid to the tank until the specified liquid level is reached. Then, turn on the jet nozzle, which is located at the bottom and side of the tank. The jet flushing method uses a mixture of gas and liquid, and the jet nozzle can effectively remove stubborn dirt from the inner cavity and surface of the workpiece. After the underwater jet cleaning is completed, the workpiece is lifted and transported to the next process by the robotic arm. All the liquid in the tank is discharged to the storage tank, and the liquid is reused after full filtration.

→ (02) After spraying, jetting, and emptying, the workpiece is grabbed by a robotic arm and enters the ultrasonic degreasing and rough washing station. The fixture basket is immersed in the tank for ultrasonic degreasing and rough washing (cleaning solution: municipal water+degreasing agent); The ultrasonic rough cleaning adopts an immersion ultrasonic vibration plate structure, which is installed at the bottom of the tank. The ultrasonic frequency is 28KHz, which can better clean the stains on the surface of the workpiece. The ultrasonic cleaning tank adopts a fast discharge structure, which can set the emptying time through the program. The ultrasonic cleaning tank is equipped with a turbulence device, mainly for cleaning the inner cavity and inner hole;

After ultrasonic rough washing, the workpiece is grasped by a robotic arm and enters the ultrasonic degreasing and finishing washing station. The fixture basket is immersed in the tank for ultrasonic degreasing and finishing washing (cleaning solution: municipal water+degreasing agent); Ultrasonic precision cleaning adopts an immersion type ultrasonic vibration plate structure, which is installed at the bottom of the tank. The ultrasonic frequency is 28KHz to further clean the residual stains on the surface of the workpiece; The ultrasonic cleaning tank adopts a fast discharge structure, which can set the emptying time through the program. The ultrasonic cleaning tank is equipped with a turbulence device, mainly for cleaning the inner cavity and inner hole.

After ultrasonic degreasing and precision cleaning, the workpiece is grasped by a robotic arm and enters the spraying, jetting, and emptying station (cleaning solution: municipal water+degreasing agent). After the fixture basket reaches the cleaning station, the operating device stops and high-pressure spraying cleaning begins. The nozzle is set above and on the side of the tank. During spraying cleaning, the liquid is thoroughly filtered before rinsing the workpiece. During the flushing process, add liquid to the tank until the specified liquid level is reached. Then, turn on the jet nozzle, which is located at the bottom and side of the tank. The jet flushing method uses a mixture of gas and liquid, and the jet nozzle can effectively remove stubborn dirt from the inner cavity and surface of the workpiece. After the underwater jet cleaning is completed, the workpiece is lifted and transported to the next process by the robotic arm. All the liquid in the tank is discharged to the storage tank, and the liquid is reused after full filtration.

→ (05) After spraying, jetting, and emptying, the workpiece is grabbed by a robotic arm and enters the ultrasonic rinsing station to undergo ultrasonic rinsing (cleaning solution: municipal water+degreaser); The ultrasonic rinsing adopts an immersion ultrasonic vibration plate structure, which is installed at the bottom of the tank. The ultrasonic frequency is 28KHz, which can completely remove residual liquid on the workpiece and improve the cleanliness of the workpiece surface. The ultrasonic cleaning tank adopts a fast discharge structure, which can set the emptying time through the program. The ultrasonic cleaning tank is equipped with a turbulence device, mainly for cleaning the inner cavity and inner hole.

After ultrasonic rinsing, the workpiece is gripped by a robotic arm and enters the spraying, jetting, and emptying stations (cleaning solution: municipal water+rust inhibitor); After the fixture basket reaches the cleaning station, the operating device stops and high-pressure spray cleaning begins. The spray nozzle is set above and on the side of the tank. During the spray cleaning, the liquid is thoroughly filtered before rinsing the workpiece. During the flushing process, add liquid to the tank until the specified liquid level is reached. Then, turn on the jet nozzle, which is located at the bottom and side of the tank. The jet flushing method uses a mixture of gas and liquid, and the jet nozzle can effectively remove stubborn dirt from the inner cavity and surface of the workpiece. After the underwater jet cleaning is completed, the workpiece is lifted and transported to the next process by the robotic arm. All the liquid in the tank is discharged to the storage tank, and the liquid is reused after full filtration.

→ (07) After spraying, jetting, and emptying for rust prevention, the workpiece is grabbed by a robotic arm and enters the mobile wind cutting station with a clamp basket; This workstation adopts a mobile air blower and a high-pressure fan. An air blower is installed inside the tank, and the air nozzle can quickly dry the residual moisture on the surface of the workpiece.

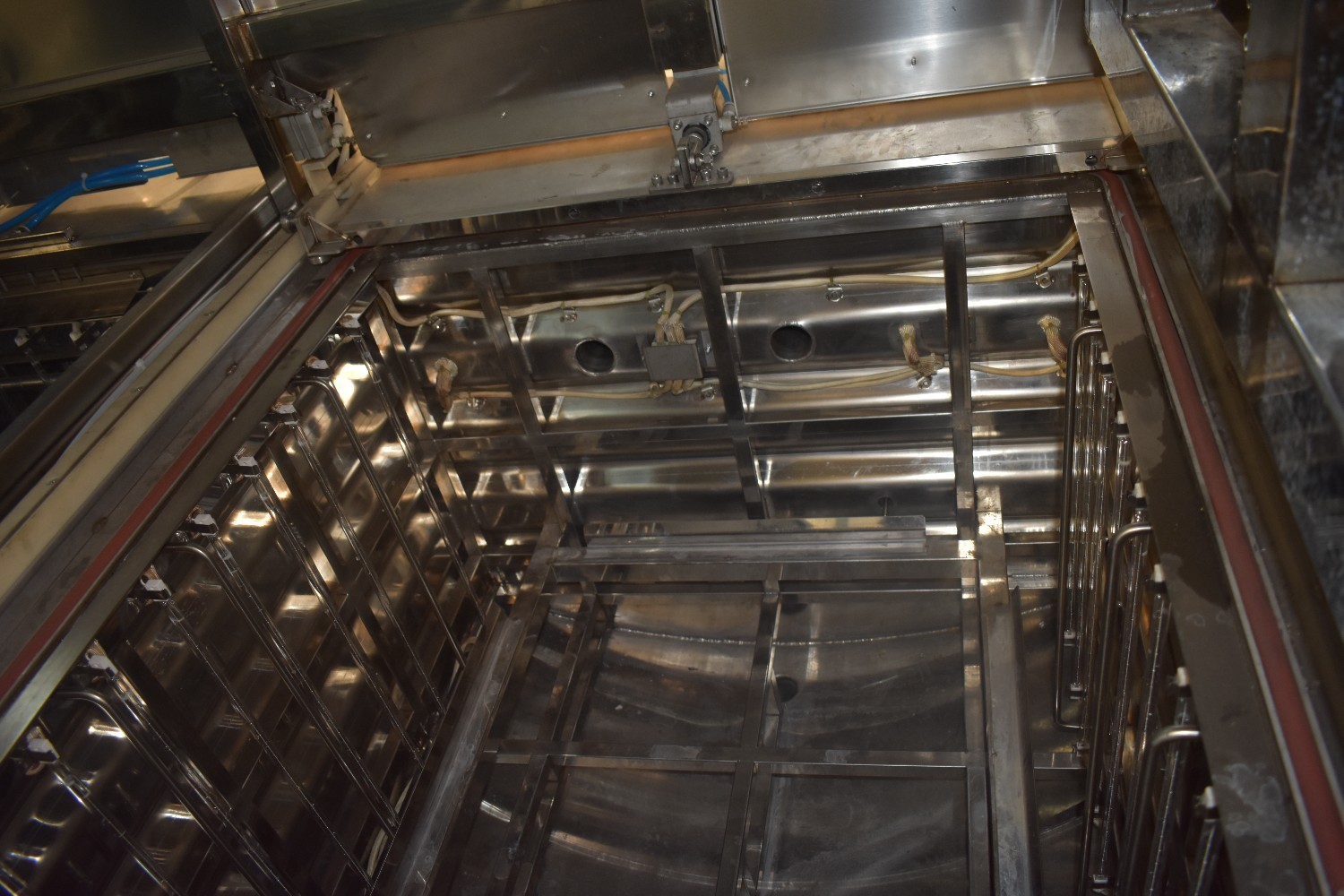

→ (08) The workpiece is subjected to high-pressure fan mobile reciprocating water cutting+fan filtered hot air pre drying, and then the mechanical arm grabs the fixture basket and enters the vacuum drying station. When the workpiece reaches the designated position, the upper cover automatically closes, and the station is sealed before vacuum drying; The vacuum drying station is equipped with a vacuum buffer tank, which can effectively shorten the vacuuming time and maintain the stability of the vacuum.

After the vacuum drying is completed, the upper cover is automatically opened, the mechanical arm grabs the fixture basket, and the motor drives the conveyor chain to automatically drive the fixture basket into the induction area, automatically positioning and transporting it to the unloading station. The operator manually takes out the product from the fixture. (The cleaning stations are arranged in a straight line, with left in and right out, and an automatic basket return line (manual loading and unloading) is set in front of them. The overall layout is in a zigzag shape, and the operators manually load and unload the materials at the first position or adjacent to each other. The overall equipment layout diagram has been approved by the bidding party.)

| Previous:Fire mask ultrasonic cleaning machine | Next:Fire mask ultrasonic cleaning machine |

TEL

TEL

Product

Product

Case

Case

Contact

Contact